HVT Testers – High Voltage Test

HVT (High Voltage Test) systems are specialized devices designed for high voltage testing, which aim to check the insulation and electrical safety of components and electronic devices. These tests are extremely important in the production of high-voltage devices, such as industrial equipment, medical devices, power supplies, and electrical components in the automotive industry.

What are HVT tests?

HVT (High Voltage Test) tests check whether the insulation between the conductive elements of the system can withstand a specific voltage without breaking down. The aim is to ensure that the device is safe to use and that its insulation will prevent accidental contact of electrical current with components that should not be live.

Scope of application of HVT tests:

-

Insulation testing:

- The quality of insulation between conductive paths, circuit components, and between sections of the device is checked.

- Insulation tests cover both PCBs and entire devices. Insulation is tested by applying high voltage between selected points on the circuit.

-

Testing of finished devices or components at the production stages:

- HVT tests are performed at various stages of production:

- For PCB boards alone, to ensure that the tracks are properly insulated.

- For partially assembled devices, to detect potential insulation problems at an early stage of assembly.

- On finished devices, to ensure their safety before they are put into service.

- HVT tests are performed at various stages of production:

-

Dielectric strength testing:

- The device is subjected to a voltage higher than its normal operating voltage to ensure that the insulation will not break down under extreme conditions.

Use of needle testers in HVT:

- The needle tester plays a key role in HVT testing, enabling precise connection to test points on PCBs or devices.

- Thanks to precise needles (probes), it is possible to:

- Applying high voltage to selected points for insulation testing.

- Quickly and accurately connecting multiple points on a board simultaneously, speeding up the testing process.

- Reduction of errors resulting from manual connection of test points.

Our HVT services:

-

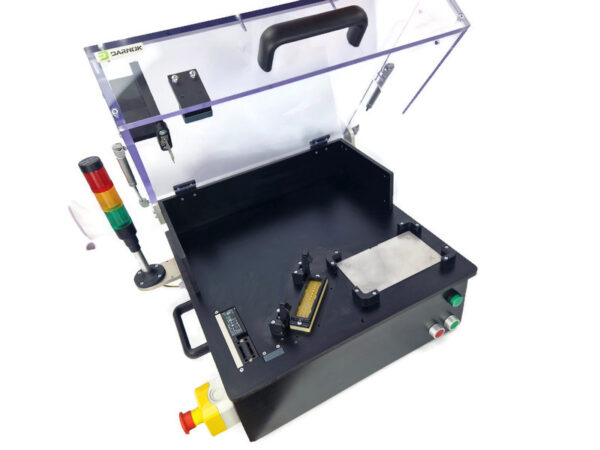

Production of needle testers:

- We create dedicated needle testers for high voltage testing, precisely tailored to customer designs. Our testers ensure reliability and safety when performing HVT tests.

-

HVT test system mechanics:

- Drilling and modification of test boards: We prepare test boards by drilling and adjusting contact points to the requirements of high-voltage testers.

- Fixture design and construction: We create fixtures and clamping mechanisms that enable repeatable and safe HVT testing.

-

Cable sheathing production:

- We design and manufacture high-quality cable sheathing suitable for high-voltage applications. Our sheathing is durable, safe, and tailored to customer specifications.

-

Construction of complete HVT test systems:

- We provide comprehensive solutions including needle testers, mechanics, cable sheathing, and control software. Our systems are ready for integration into the production line and meet all safety requirements.

-

Insulation testers:

- We offer the production of dedicated insulation testers that precisely check the quality of insulation on PCBs and in finished devices.

Benefits of our HVT solutions:

- Precision: Dedicated needle testers enable accurate and safe connection to test points.

- Comprehensiveness: We offer full support in the field of mechanics, cable sheathing, and the production of testers and complete systems.

- Customization: All our solutions are tailored to specific customer requirements, ensuring the highest quality and reliability.

- Safety: Our systems are designed with the highest safety standards in mind, which is crucial when working with high voltage.

Summary:

HVT (High Voltage Test) systems are essential in the production of high-voltage electronics, enabling the verification of insulation and safety of devices at various stages of production. The use of needle testers allows for quick and precise testing. Our company offers comprehensive solutions including the design and manufacture of needle testers, mechanics, cable sheathing, and entire HVT systems tailored to individual customer needs. In addition, we specialize in the creation of insulation testers, which are key to ensuring the reliability and safety of devices.